1 / 3

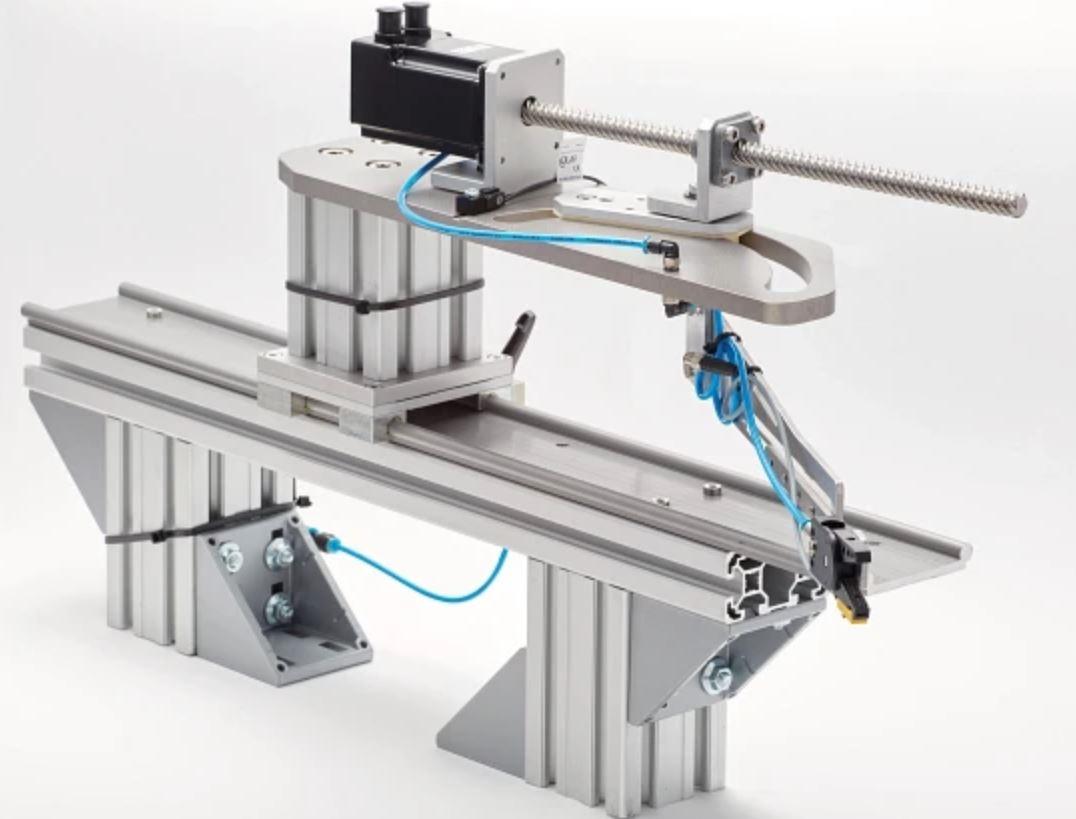

1 / 3Sprue picker: Removing and separating sprues from the injection molding Machine

Hardware Price:

Pickrate

1,25 sec.

For continuous use

24/7

suitable

Operation

100% lubrication free

Efficient Injection Molding with the IAP1 Sprue Picker:

Cost Savings and Automation

Automation is a key driver for optimizing operational processes and improving competitiveness in injection molding. The IAP1 sprue picker offers an affordable solution for automating sprue removal and separation, ideal for small injection molding machines. By engaging laterally within stripper and ejector molds, the picker eliminates manual handling tasks, accelerates workflows, and ensures economical production. With a cycle time of just 1.25 seconds, the IAP1 delivers fast results and a payback period of only a few months.

What is the Application?

The IAP1 sprue picker automates sprue removal and separation in injection molding machines, significantly reducing manual labor and enabling streamlined processes.

What are the Advantages of the Solution?

Faster Production: Total cycle time from opening to closing is only 1.25 seconds.

Cost-Effective: Quick payback ensures affordable entry into automation.

Versatile Design: Configurable base adapts to various machine types.

What are the Advantages of the Robot?

The sprue picker offers reliable performance with:

Electric Drive: Ensures precision and energy efficiency.

Compact Size: Operates effectively in confined spaces.

Easy Maintenance: Wear parts can be easily replaced for minimal downtime.

Transforming Injection Molding with Automated Sprue Removal

The IAP1 sprue picker streamlines injection molding processes, reducing labor costs and improving efficiency. By automating repetitive tasks, small-scale operations benefit from faster production, improved reliability, and enhanced cost savings—making it a competitive solution for modern manufacturing.

1 Component